SIEMENS CENTER OF EXCELLENCE ON ELECTRONICS AND INSTRUMENTATION LABORATORY

| Name | Description | Instruments/Softwares |

|---|---|---|

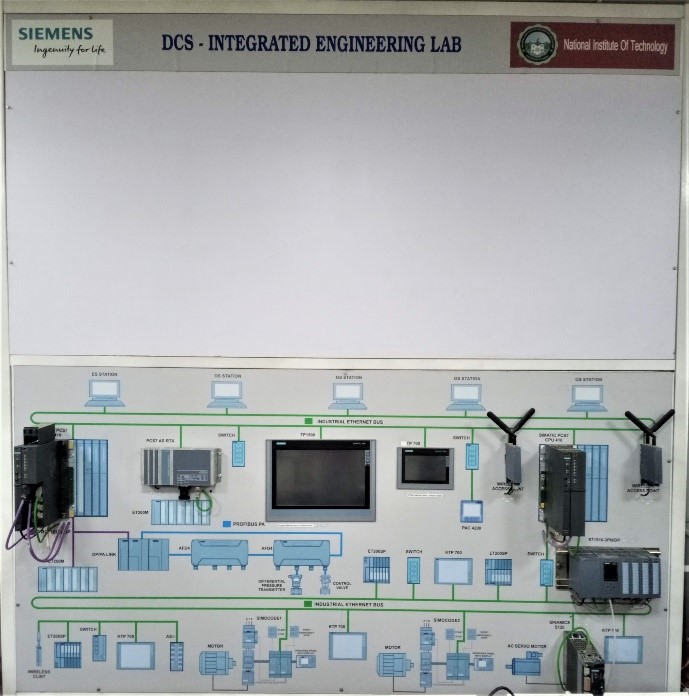

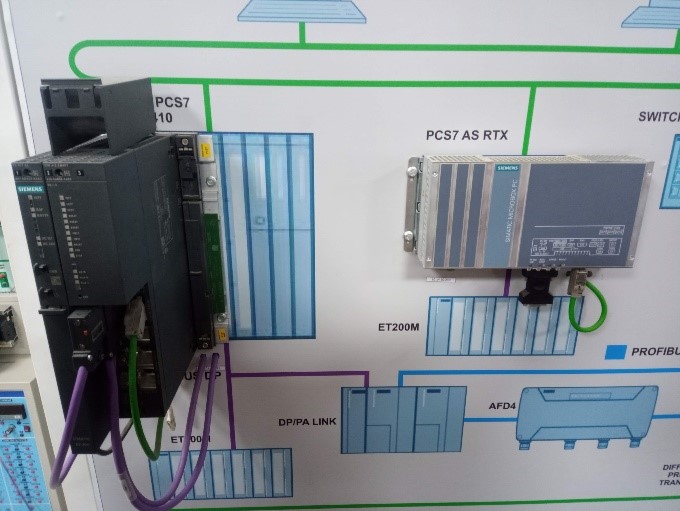

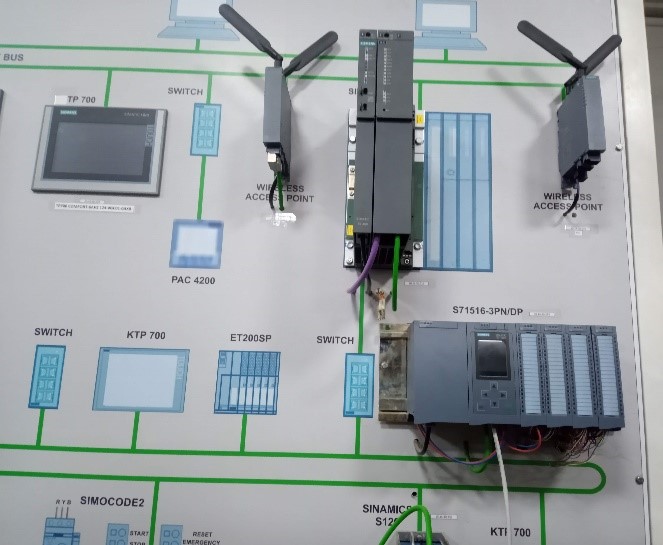

| DCS (DISTRIBUTED CONTROL SYSTEM) CONTROL PANEL | Monitoring and control of all the equipment and machines in all the laboratories in the Institute using Integrated Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) in order to establish a

Centre of Excellence which will cater to the need for higher semester laboratories and Research. The whole idea is to integrate the existing Power Systems, Electrical Machines and Drives, Power Electronics and

Control Systems Laboratories and also to establish a private Cloud using the existing networking facilities. However, this laboratory can be used as Distributed control system (DCS) lab, Programmable logic control

(PLC) lab, Process control lab, IoT (Internet of Things) lab, Solar energy lab and extended for project work which will be available for undergraduate (UG) students and postgraduates (PG) students.

Same laboratory will be available for research activities related to IoT (Internet Of Things), Process control. Control system and Distributed control system. The DCS and PLC mainly used for branches

such as EIE, EEE, CSE, and ECE and it is highly required to conduct Real-Time hands-on exercise for the embedded system subjects and laboratories. Laboratory for the benefit of B. Tech, M. Tech. and

Research Scholars. These initiatives are intended to bridge the gap between industry requirements and technical education system by providing solutions which make technical institutes more aligned with

industry needs and graduate students’ industry ready. We offer programs to foster, empowering students and professionals with state-of-art knowledge and Technological skills with centre of excellence by

providing real-world experience. Hardware:

|

|

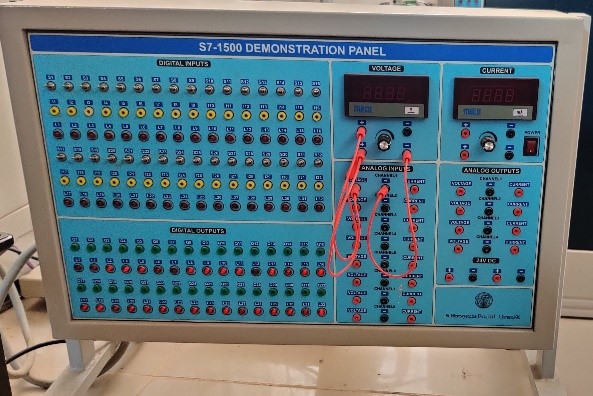

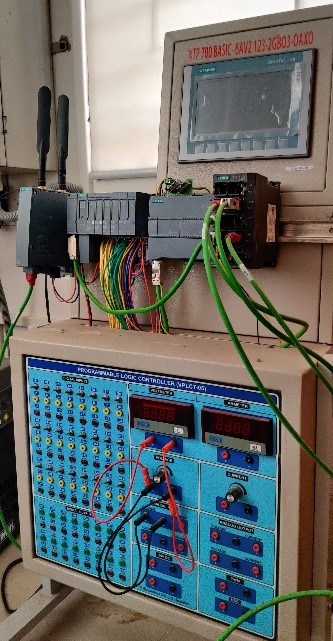

| S7-1500 DEMONSTRATION PANEL | The SIMATIC S7-1500 controller family with the Totally Integrated Automation Portal (TIA Portal) offers you numerous new options to further increase the productivity of your machines and to make the engineering process even more efficient. Explore the options in this Getting Started. In the first basic steps, you will get to know the new hardware better. We will also show you how to configure and program the SIMATIC S7-1500 with SIMATIC STEP 7 V13 (TIA Portal). The connection of a SIMATIC HMI Comfort Panel with SIMATIC WinCC Advanced V13 (TIA Portal) or SIMATIC WinCC Professional V13 (TIA Portal) completes the basic steps. |  |

| PROGRAMMABLE LOGIC CONTROLER (VPLCT-05) | PLC trainer consists of a PLC, Demonstration panel and programming software to develop the program in ladder language, so that students can study the programming techniques, different control functions, Real time applications and implementation of logical approaches that causes conveniently replace small and medium wiring systems. PLC hardware consists of CPU, input & output module. Demonstration panel consists of SPDT switches, LED lamps, 3½ digit digital voltmeter, 3½ digit digital ammeter (0 - 200mA), Banana connectors and fuses provided to demonstrate the Digital & Analog input/output functions by PLC. A point to point interface communication cable provided to interconnect PLC with PC |  |

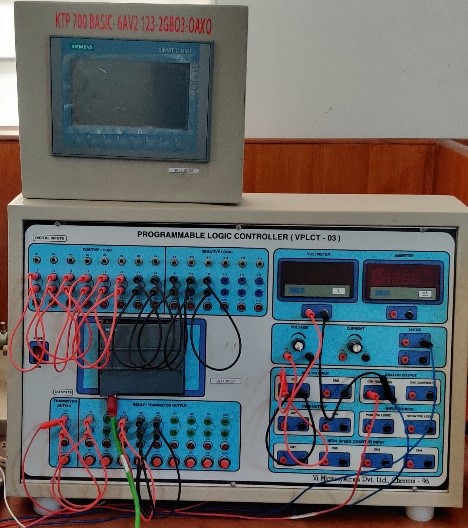

| PROGRAMMABLE LOGIC CONTROLER (VPLCT-03) | SIEMENS PLC S7-1200 1214C AC/DC/RLY 6ES7 214-1BG40-OXBO: PLC combines a microprocessor, an integrated power supply, built-in PROFINET, webserver, high-speed motion control I/O (14 Digital input, 10 digital outputs, 2 Analog inputs and 1 Analog output) in a compact housing to create a powerful controller. SIEMENS HMI KTP700 BASIC 6AV2 123-2GB03-0AX0: 7” display for control and monitor the plant operation, 800*480 pixel, 64k colors, key and touch operation, PROFINET for communication with PLC or DCS. |

|

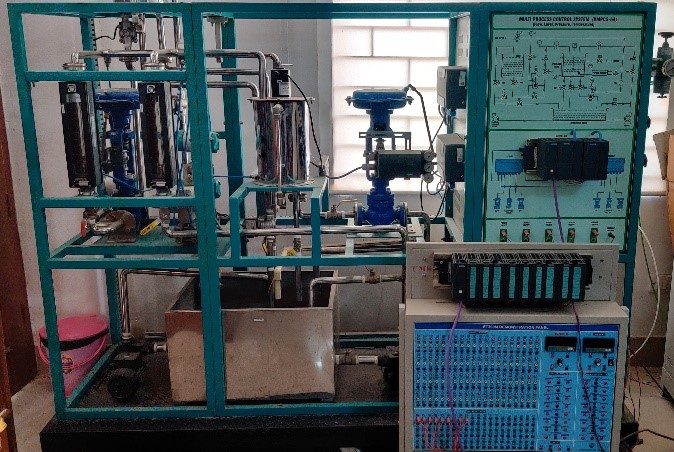

| MULTI PROCESS CONTROL SYSTEM (VMPCS-64) (Flow, Level, Pressure, Temperature) | MULTI PROCESS CONTROL SYSTEM Interfaced with DCS via PROFIBUS DP to control Flow, Level, Pressure and Temperature. Differential pressure transmitters (PROFIBUS PA) are connected for measuring Flow, Pressure and Level. RTD is connected for Temperature measurement. Control valves are connected in inlet and outlet of the process tank to manage the flow. Heater is fixed in the process tank and connected with DCS via Eurotherm Power Drive. Profibus slave device ET200M is interfaced with DCS to control the Pump, Heater and Stirrer via field digital outputs. |

|